Why in the center? sure, if you put them in the center you get the least angular difference over the suspension travel, however you can also put them in the correct posiyion so they have the same angular change over travel as the steering knuckle has resulting in absolute 0 bumpsteer.

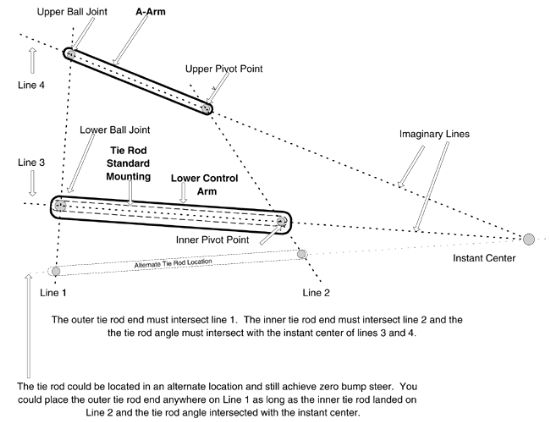

Look at this picture, it's all about extending the ball joint to cross shaft lines, where they cross you have your instantaneous center, then from there go to the steering arm. Where all this intersects the line between the 2 cross shafts is where the tie rod end should be, the angle can be fine tuned by spacing the steering arm side. It will be difficult and time consuming to do but you should be able to get it very close to ideal, that sure makes fine tuning easier later on 9w/ bumpsteer measurements) I did all that with the entire front clip off the car, much easier that way and I know you won't be able to do that.

What they call "alternate" position is where the tie rod will roughly be, slightly lower than the lower control arm.

Where it says line 2 you see the inner pivot for the tie rod, THAT'S where the hole in your rack's center plate should be. I know you spoke to Norvalwilhelm about this, look at his pics, that's exactly the position of the eye on his center link, he modified the stock one to reposition the mounting hole.

Don't worry about line 1, it's purely theoretical, there's no way the line will be in the same plane as the 2 balljoitns since the steering arm is further back and you have to accout for the ackerman geometry putting the steering arm hole slightly further inboard from the spinde steering axis.