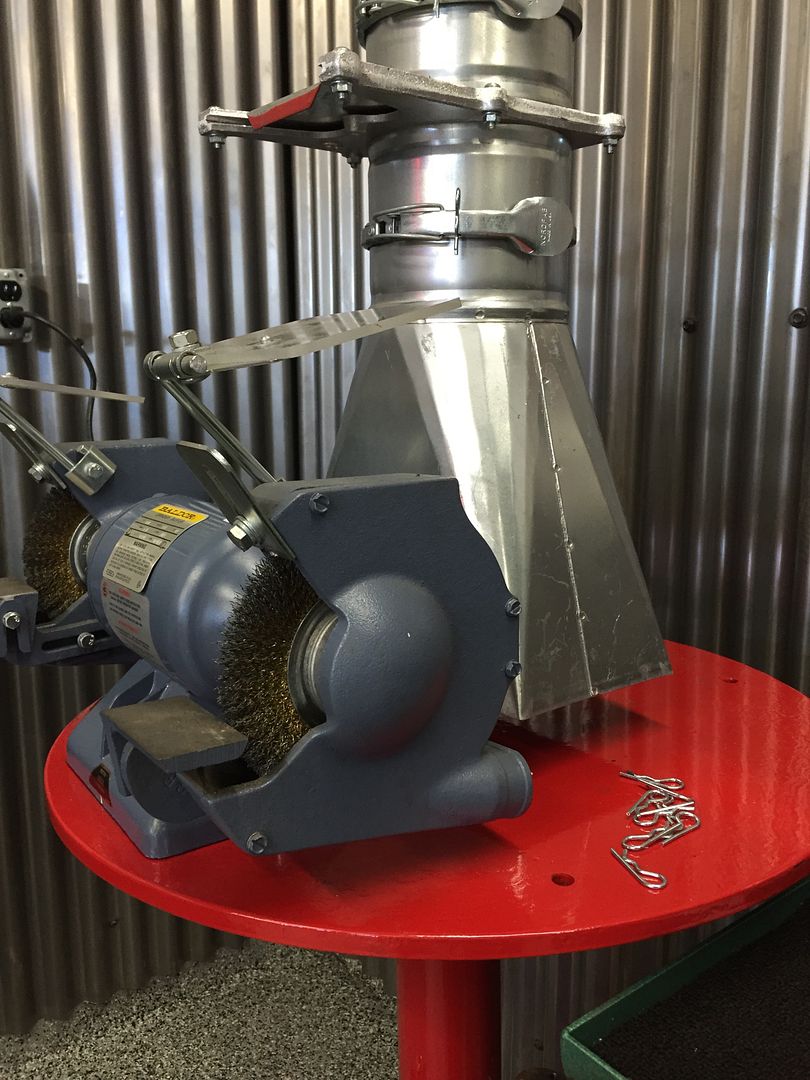

First you need a "DUST COLLECTOR" --- but don't forget to add a SPARK ARRESTOR (the blue piece) lest you start your dust collector on fire!!

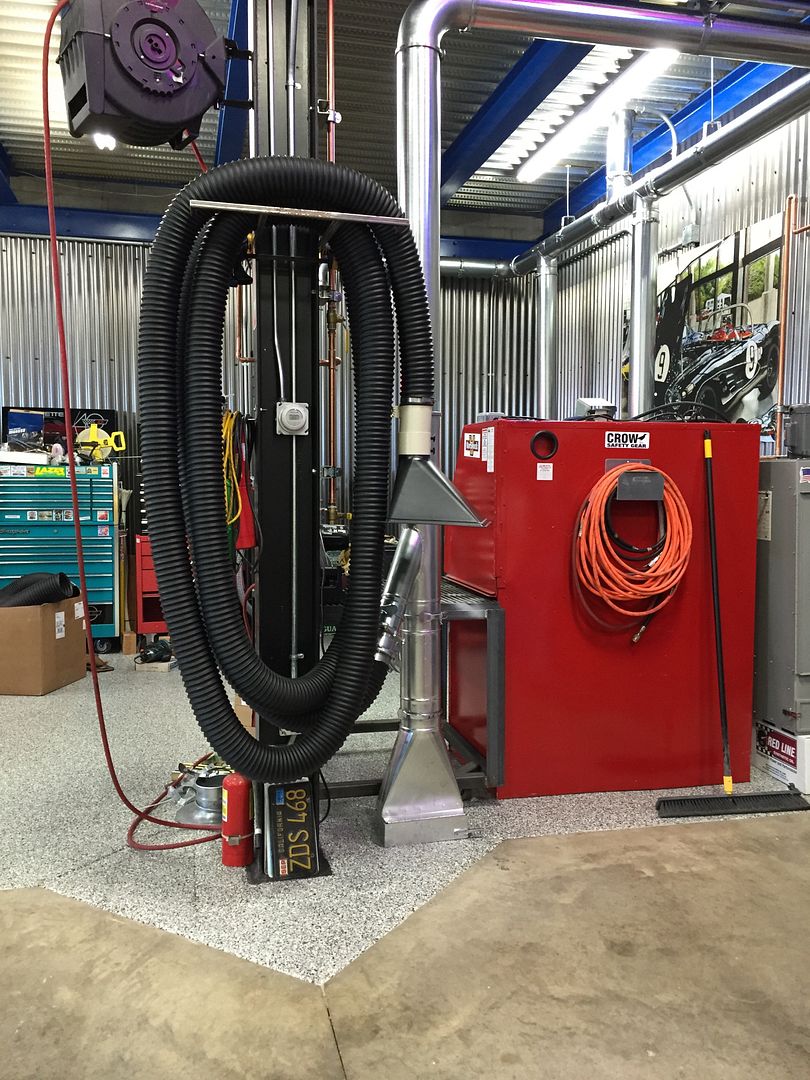

These pictures were all taken during the build out process so nothing is tidy'd up yet.... but you'll get the drift.

Then get yourself a bunch of parts and pieces from NORDFAB DUCTING. The beauty of this stuff is it goes together with clamp bands and can be adjusted or moved or taken apart and moved... Added to or subtracted from as needed.

The 4" hose X 40' of it - allows me to put the "big mouth" (Grizzly Tools) either on a stand it came with -- or just toss it inside a car etc.... ALL of this is controlled by METAL blast gates to control the suction where I need it.

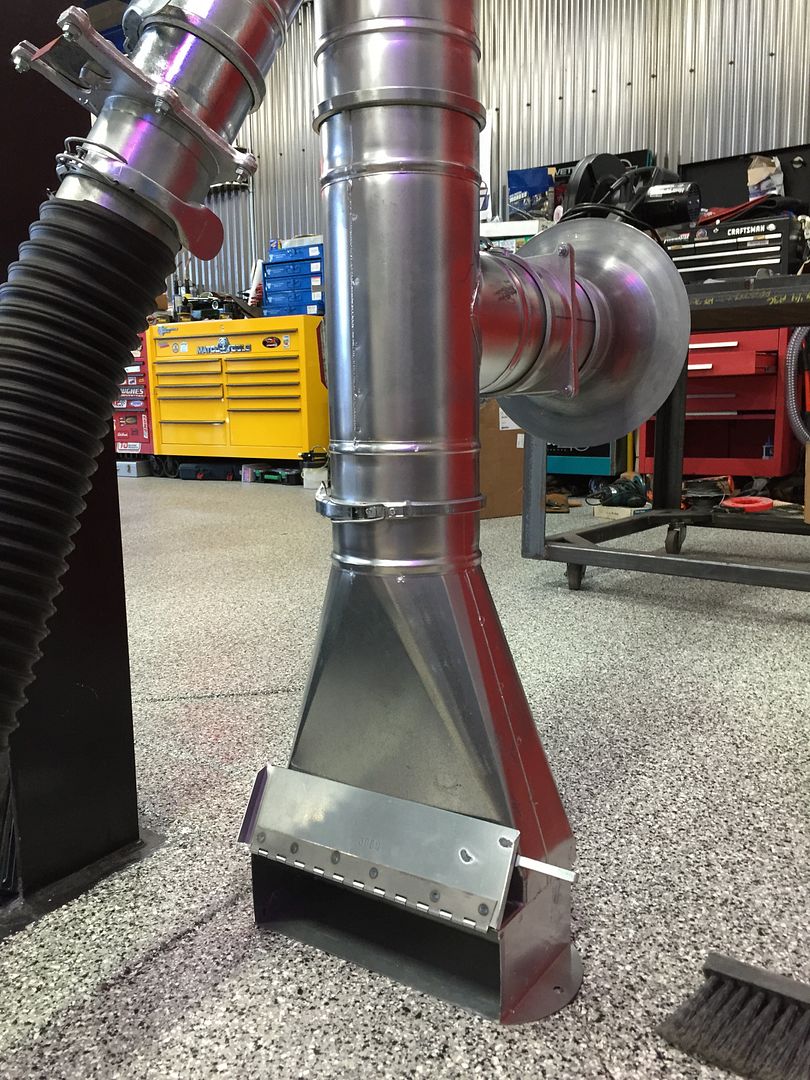

This leg - has the 4" "big mouth" on a Y -- and then a bell mouth pick up that will be fabled into a sheet metal "tub" that is being built to go under my grinding table (has a grated top)..... shut off the 4" --- or shut off the 6" grinding table with the blast gate - and kick up the "toe kick" dust pan. This is towards the front of the Lift in my shop..... I can just grab a push broom and push the crud this direction and up she'll go!!